In the world of pocket squares there are major differences between the offerings of different fashion brands. Pocket squares until four or five years ago were not readily available in many stores. It was not until after 2008 that we began to see their resurgence. Some tailoring houses, especially those on Savile Row, will tell you that they never stopped selling pocket squares (pochettes in French), and they would not be lying, but those stores are few and far between than the ones currently marketing their goods on websites such as Mr. Porter. Of all the web stores out there, Mr. Porter has the greatest selection of pocket squares and for this reason I am using their current selection to show you a few points about these little squares.

1. What is the ideal dimension?

Amongst the sartorially inclined old world - the 42 x 42cm is considered the most luxurious full bodied pocket square however with the changing of the guard and the breaking down of traditions, the slimming up of lines and the tightening of pockets, there has been some push towards the 36 x 36cm pocket square. The reason is that the 42 x 42cm on a modern suit can push the breast pocket out and alter the contours of the suit. In this case, it is a question of how much dandy do you want? If you are likely to make a rose or a fist out of your pocket square, the bigger the better. If you are wanting squarer lines, go the smaller.

2. What sort of fabric do I want for a pocket square?

Silk is preferable according to tradition. However, recently I had a dialogue with my friend Giovanni from Milan who said 'I don't want a shiny thing in my pocket, can you make me one with dull colours for a normal day wear jacket'. He was right of course, Italians are always right when it comes to fashion. There are times when you are wearing a cotton jacket or a dulled sports jacket where silk looks too opulent. In this case I would recommend cotton, linen/cotton and maybe even try the Drakes of London wool squares. Whatever you do, don't use synthetics.

3. Woven, digital printed or screen printed?

It is a matter of horses for courses. The most revered pocket squares are the screen printed variety or what some term 'corrosive printing'. To be frank, I do not know enough about corrosive printing to offer a detailed description of the process involved, suffice to say that it is a technique where the ink is allowed to bleed through to the other side of the silk. It is, from my understanding, a form of screen printing.

The process involved in a screen printing is exceptionally long winded, far more than digital printing, which is why it is more highly sought after. Brands such as Turnbull & Asser, Charvet and Hermes are famous for their screen printed silk squares. Often the process starts with developing a screen which can cost anywhere from 150 euros to 500 euros or more. In the case of Hermes, the set up costs, given the number of colours they run, is very high, hence the price tag they ask for on some of their more elaborate designs. What is more, the process of screen printing, which to this day is mostly done by hand, is labour intensive and subject to more human error owing to the amount of labour. To develop a screen, most companies insist upon a minimum number of metres to run in the chosen silk to make the set up viable for them. Often companies will ask for a minimum 100 metre run of silk per screen design. Although one can change the colour combinations of this run, it must be in the one design (the screen).

In my experience, the best pocket squares in the screen printed variety are made on 12 to 16 mommes silk twill. Twill, which has its grain on the 45, is the ideal fabric to use for printing. Why twill seems to take the ink so well is still a mystery to me and has not been answered by any of my contacts.

Woven silk is a completely different process from screen printing. Woven silk is very similar to the existing silk ranges we have here for our bow ties at Le Noeud Papillon. The silk is made using a jacquard loom using a much lighter warp and weft of silk. The beauty of a woven silk pocket square is texture. In an example I own from Hermes, the silk has been woven with an H running through the satin. This is a very unique technique and requires a very special loom and silk to ensure the lightness of the pocket square at the end of production. Below is an example of a woven pocket square from Alexander McQueen. By enlarging the image you will be able to see that the logo is woven into the pocket square as opposed to being printed. Whilst I was once only interested in screen printed pocket squares, I am slowly coming around to the woven variety after seeing a number of samples of Brioni and Stefano Ricci pocket squares in Italy.

Digital printing has taken over the market for pocket squares. It is now dominating the bulk of pocket squares available. There are some reasons that one would choose a digital pocket square and they are reasonably obvious. Given that screen printing permits a smaller number of colours and that set up costs are very high and that there is a heavy reliance upon human labour, many companies are turning to digital printing to put their designs into play. The cost of digital printing is substantially lower to set up your design and the designs are limitless because in digital printing you are able to print whatever design you want - even, for example, a family portrait. In the age of Adobe Illustrator and Photoshop, it is therefore preferable that many designers are able to translate their designs exactly as they create them - and for this reason, we are seeing more and more companies turn to digital printing. The flip side is that the ink will not sink through to the backside, so you are left with a ghosting effect on the underside of the pocket square.

TIP: Many websites have a funny little thing that they do to prevent you working out whether it is digitally printed or not. They fold the pocket square over by two folds so as not to reveal the underside.

4. Do I need a roll stitch?

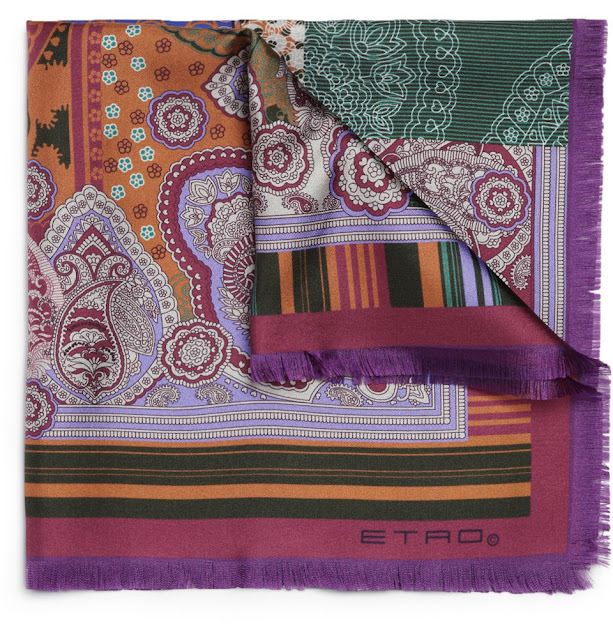

The answer is no. Roll stitching, especially hand roll stitching, is very much a prestige element to pocket squares which gives the owner an element of pride in the pocket square, a certain artisan touch. However, when trying to create square lines on a pocket square, especially in the vein of Mad Men, nothing gets more in the way than a roll stitched hem. Again, it is simply a matter of horses for courses. If you are making an elaborate display of your pocket square, a roll stitch is better. If you are going for straight lines, maybe not. It all comes down to the look you are trying to create on that particular day.

|

| An example of a woven pocket square by design house Alexander McQueen |

|

| An example of a non roll stitched hem - a frayed hem, by Etro |

|

| By all accounts, the ghosting effect on the underside indicates that this is likely to be a digitally printed pocket square |

|

| A classic. Judging by the edges you can see that this is a twill silk by Turnbull & Asser. This is an example of a delightfully light screen printed pocket square. |

No comments:

Post a Comment